| Business Type | Manufacturer, Exporter, Supplier, Trader |

| Condition | New |

| Application | Labouratory Use |

| Feature | Durable, Easy To Use |

| Click to view more | |

Product Details

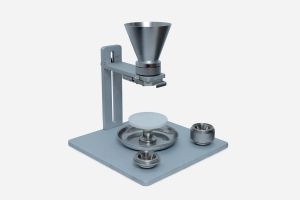

Keeping high standards and quality as a priority, Raise Lab has emerged with a motto to be the leading source of lab equipment. Its recent and advanced Tablet friability testers stand as an example.

Why does a tablet need friability testing?

Have you ever noticed crumbled or chipped tablets in any package you bought from a pharmacy? Such are a big no in the pharma industry as they are ticked poor. A solid tablet by a leading manufacturer should undergoes friability testing to rule out any possibilities of being crumbled or chipped during packaging or transporting.

Benefits of equipping a friability tester in lab

- Tablets with a poor tag are not approved by a quality control lab and this could be a big disadvantage for pharmaceuticals aiming for high production values.

- For a pharmaceutical to pass the quality control, the tablets must be strong enough to withstand crumbles or shocks during porting, packaging or coating. A friability tester makes sure to approve only high-quality tablets that are durable and shock proof before they are coated.

- For researchers, the friability testers are a big boost up as they aid in analyzing the reasons for breakage and reconstruction of the binding formula.

- Tablet friability testers are always an added advantage for pharmaceuticals and quality control labs to be leading and reliable.

Types of friability testers

- Depending upon the need and runtime, or the personal equipment and affordable choices of the manufacturers, single drum, double drum or triple drum testers are mostly and widely used. The commonly chosen tester is a double drum for its easy-to-use technology. The more drums a tester has the more varied samples it could test at the same time. This saves the pharma lab time and equipment.

- Raise Lab promotes and manufactures only top-quality friability testing apparatus that meets the international quality standards and aims at accuracy besides reliability. We ensure patient’s safety and end consumers’ satisfaction of receiving top-notch products.

- Elevate Your Quality Assurance with the RFT-1 Digital Friability Tester

- Step into a new era of quality assessment with the RFT-1 Digital Friability Tester. Meticulously engineered for precision and reliability, this model is a testament to our commitment to excellence. Ensuring your pharmaceutical testing is seamless and accurate, the RFT-1 stands as a beacon of innovation.

Unveiling the Features:

- Streamlined Design: Equipped with a single friability drum, this apparatus offers an intuitive and ergonomic splash-proof panel.

- Enhanced Display: The 20 x 4 character LCD Display provides real-time updates, ensuring you’re in the know at all times.

- Precision at a Glance: Real-time display of RPM (Revolutions Per Minute) allows you to monitor testing speed effortlessly.

- Modern Efficiency: Designed for modern needs, it accommodates 1 test, embodying simplicity and accuracy.

- Automated Convenience: After each test, the apparatus automatically dispenses the sample, streamlining your workflow.

- Transparent Visibility: The transparent acrylic drum guarantees enhanced visibility, enabling you to closely observe the testing process.

- Comprehensive Documentation: IQ/OQ Documentation elevates your experience, offering insights into the equipment’s performance and ensuring compliance with industry standards.

Designed to Meet International Standards:

The RFT-1 Digital Friability Tester isn’t just a technological marvel; it’s also aligned with the USP (United States Pharmacopeia) and EU (European Union) norms. This means your quality assessments are not only cutting-edge but also adhere to globally recognized standards, ensuring that your products meet the highest quality criteria.

Whether it’s about embracing modern design, ensuring accuracy in testing speed, or automating the process, the RFT-1 stands ready to transform your quality assessment procedures. Say hello to a new level of precision and reliability that aligns with international benchmarks.

Looking for "Tablet Friability Tester" ?

Explore More Products